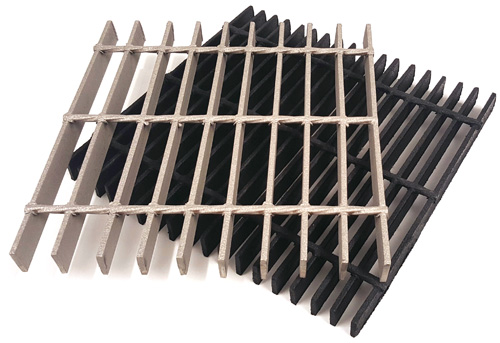

Floor gratings are metal formed grid patterns made to provide traction and allow for water drainage over an opening. Because grating is strong and lightweight, it is popular for a wide range of uses. Grating applications include treading, barrier creation, building material, ventilation, drainage, load bearing and decoration ratings are common in industrial and commercial facilities and are used in production plants and on sidewalks where liquid or debris may be present. The increased tread of a floor grating helps to improve safety by preventing water buildup or allowing a walking surface to become slippery. Read More…

All Plastics and Fiberglass prefabricates gratings products including fiberglass gratings, bar gratings and floor gratings. We offer online ordering of our in-stock products to accommodate all our current and potential customers.

Our seasoned engineers are experts at manufacturing durable gratings. These high quality solutions are specialized for a variety of industries. We take pride in saying that all of our manufacturing processes happen right here in the United States. We promise to assist you with all of your needs. You will be satisfied with our long-lasting economical solutions!

We are the experts at creating high quality gratings. Our engineers are eager to handle any of your requests. We care about your order, no matter how big or small. You can count on friendly assistance from the first call. We pay attention to your specific requirements and you are guaranteed to receive your products on-time. These items are easy to install and simple to maintain.

For over 40 years, Ohio has been a leading manufacturer of precision made aluminum grating solutions and offers products in both light duty for pedestrian loading and heavy duty for H20 loading to meet AASHTO standards. Ohio’s products can be manufactured to comply with ADA requirements, are manufactured in the USA and can assist with earning LEED credits. Please call Ohio today!

More Floor Grating Manufacturers

It is not uncommon for municipal and federal laws to require different types of facilities to use floor grating on walkways or in areas where there is a potential for fluid leakage.

To allow for airflow in a building, grating is often integrated into the ventilation system. Beyond functions such as these, grating can be used to provide shade, be a handrail support, act as decoration, or function as an ornamental screen.

The History of Floor Gratings

People have been producing metal grates more or less since they have had metal. They first cropped up during the Bronze Age. One example of them comes from the Italian city of Elea (later known as Velia), which was controlled by Rome by the 3rd century BC. There, they had a street with drainage grates that acted as gutters.

By the 11th century, floor grates were also used in home heating to hold coal at the bottom of fireplaces. Floor grates from this time were primarily made from cast iron and steel. They were much more ornate than modern floor gratings, which are now made more for function. Sometimes, for aesthetics, people still do request antique-looking or authentic antique gratings.

Over the years, another popular application of floor gratings has been sewage draining. In 1884, James T. McHugh received a US patent for sewage grating.

Today, manufacturers fabricate floor grates for not only the aforementioned uses, but also for countless other applications, such as industrial flooring and safety. Part of the reason they have been able to diversify floor grating uses so successfully is the fact that they can make them with far more materials than before. One popular example is fiberglass. As the years go on, we can expect floor grating manufacturers to use even more diverse materials.

Design

Production Process

Manufacturers fabricate floor grating grid patterns using a wide variety of processes, including: welding, metal plate expansion, perforation, pultrusion and/or molding. They may follow up any of these processes with hot-dip galvanization.

Welding is a popular way to make extremely rigid floor gratings. Manufacturers perform welding, or fusing via heat, on metal or fiberglass bearing bars. Mostly, welding, along with riveting and swaging, is used to make floor grates used as platforms, trench grates, safety barriers and walkways.

Metal plate expansion involves slitting and expanding metal sheets into predetermined sizes. Manufacturers like to use expanded metal to reduce waste.

Metal perforation involves creating hole patterns via a punch or a press.

Pultrusion is an automated process during which impregnated bar resins are pushed through a die. Pultrusion is most popular for fiberglass grate fabrication. Pultrusion is valued for its high quality, repeatable results.

Molding of gratings begins when manufacturers manually layer the materials until they reach the chosen thickness of the grate-to-be. Then, they place the grate inside a mold, where it sits until it cures. This process is used to make reusable plastic gratings and FRP gratings.

Hot dip metal galvanization is a strengthening exercise. To perform it, manufacturers dip newly formed metal gratings in a bath of hot zinc oxide. Hot dipped galvanized gratings are extra resistant and protected against oxidation and corrosion.

Materials

Manufacturers usually make floor grates using strong metals like: iron, carbon steel, stainless steel, galvanized steel or aluminum. Often, they also use reinforced plastic or fiberglass. Manufacturers select materials based on material properties like: strength, flexibility, corrosion resistance, abrasion resistance, etc.

Considerations and Customization

Depending on the application, manufacturers can make floor gratings in many different thicknesses, dimensions and patterns. They determine patterns based on the required strength properties of the floor grating and the architectural needs of the application. Examples of architectural needs include: how they want fluid to flow, how much traction they seek, the percentage of area on the grid that must be open to water, and the amount of light that must pass through the grate. Common patterns include: ovals, diamonds, and squares, though manufacturers also design custom patterns.

Types

Heavy-duty gratings are welded or created with pressure-locked bars. Floor grates like this are less likely to warp over long periods of time.

Trench grates, also known as floor trough grates, can be found in industrial facilities and even on city sidewalks. These long and narrow grates double as a drain gate that people can walk across while still giving workers an access point to pipes and systems underneath.

Stair treads are grates featuring cut-out holes with serrated tooth inner diameters. They are designed to prevent people from slipping on the stairs. Made using expanded metal or perforated metal, stair treads do not allow for mud, water, or other materials to build up.

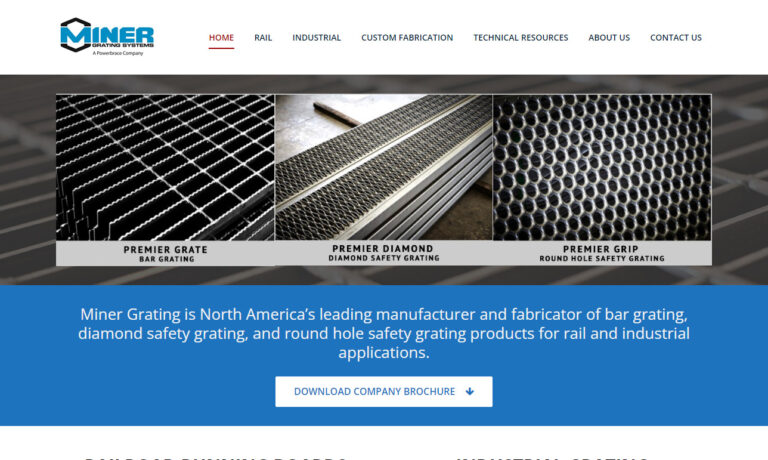

Bar grates, or bar gratings, are made with load bearing and cross metal bars machined together for strength. Typically, bar gratings are used as mezzanine decking, walkways, stair tread, platforms and the like.

Metal gratings are used to support non-slip surfacing, surface filtration and high strength applications.

Steel grates and stainless steel grates are used for all the same applications as other metal gratings, plus applications in highly corrosive environments.

Fiberglass grates, or FRP grates, are lightweight, slip-free and immune to rust and fire. Fiberglass gratings work well as stairs and floors where floor strength is extremely important.

Plastic grates are lightweight, slip-free, easy to install, invulnerable to rust and flame retardant.

Floor drains are grates used in plumbing to remove standing water from the floor.

Architectural are lattices integrated into builds for the purpose of aesthetics or function. Architectural grates may be metal or fiberglass.

Advantages of Floor Gratings

Objects that serve a similar function as floor grates include floor vents, floor registers, and floor tiles with perforations. Floor vents and floor registers are designed to allow air to flow between different areas of a building, facilitating ventilation and heating or cooling systems. These objects typically have slatted or perforated surfaces, enabling air to pass through while providing some structural support for foot traffic. On the other hand, floor tiles with perforations are often used in wet or outdoor areas to drain water and prevent puddling.

Despite serving similar purposes, floor grates have several advantages over these alternative objects. First and foremost, floor grates are specifically engineered to support heavy loads and constant foot traffic without compromising their structural integrity. This robustness makes them ideal for use in industrial settings or places with high footfall, where durability is crucial. In contrast, floor vents and registers, while functional for air circulation, may not withstand the same level of wear and tear.

Another advantage of floor grates lies in their versatility and adaptability. They come in various materials, including steel, aluminum, and even durable plastics, allowing for customization to suit different applications. Furthermore, floor grates can be designed with specific patterns or shapes to enhance aesthetics while efficiently serving their purpose. This versatility makes them suitable for a wide range of environments, from commercial spaces to outdoor pathways.

Moreover, floor grates offer a more practical solution for areas prone to water accumulation or spills. While perforated floor tiles may drain water, they lack the added benefit of providing a continuous surface for people to walk on. In contrast, floor grates have gaps that efficiently channel water away, preventing slips and falls in wet environments.

In conclusion, while floor vents, floor registers, and floor tiles with perforations serve similar functions to floor grates, the latter stands out due to its superior durability, versatility, and drainage capabilities. These advantages make floor grates an excellent choice for various applications, especially in areas where heavy loads, constant foot traffic, and efficient water drainage are essential considerations.

Accessories

Floor grate accessories play a crucial role in ensuring the proper installation and functionality of floor grates. Here’s a discussion of various accessories and their specific purpose:

Washers

Washers are flat, thin discs with a hole in the center. They are used to distribute the load and provide a smooth surface between the floor grate and the bolts or fasteners. Washers prevent damage to the floor grate material and help ensure a secure and even attachment.

Bolts and Fasteners

Bolts and fasteners are used to secure the floor grate to its frame or base. They come in various sizes and materials, such as stainless steel, galvanized steel, or brass. Choosing the appropriate bolt or fastener is crucial to ensure a strong and reliable connection between the floor grate and the supporting structure.

Locks

Locks are devices used to prevent unauthorized access to certain types of floor grates, such as those used in outdoor public spaces or industrial areas. These locks may be integrated into the design of the floor grate itself or added as additional security measures.

Butterfly Clips, Hold Down Clips, and Hold Down Clamps

These accessories are used to hold the floor grate securely in place and prevent any movement or rattling during use. They are particularly important in applications where the floor grate may be subject to vibrations or heavy loads. The choice of the specific clip or clamp will depend on the type of floor grate and its mounting requirements.

Channel Connectors

Channel connectors are used to join multiple floor grates together, creating a continuous surface. They allow for expansion and contraction of the floor grates due to temperature variations, ensuring the overall stability of the floor system.

To determine which floor grate accessories are needed for a specific application, several factors should be considered. These include the type of floor grate being used (material, size, and load-bearing capacity), the installation location (indoor or outdoor, wet or dry area), the expected foot traffic or load intensity, and any specific safety or security requirements. Consulting with a knowledgeable supplier or an engineer can help in making the right accessory choices for a particular application.

Acquiring these floor grate accessories can be done through various channels. Local hardware stores or construction supply outlets often carry a selection of standard floor grate accessories like washers, bolts, and fasteners. For more specialized or custom accessories, contacting manufacturers or distributors that specialize in floor grate products may be necessary. Online retailers and industrial supply websites can also be good sources for a wide range of floor grate accessories. It’s essential to ensure that the chosen accessories meet the specific requirements and are compatible with the floor grate being used. Additionally, considering factors like material quality, load capacity, and durability is crucial to ensure a safe and reliable installation.

Installation

No two floor grate installations are the same. However, to help you along the way, we offer the follow tips:

- If working with bar gratings, install your bar gratings with the cross rods on the top size. This creates more strength.

- Install (at smallest) a 1” bearing along with your bearing bars that are 2 ¼” or smaller. (These are usually provided.) If your bearing bars are 2 to 2 ½”, install them with 2” bearings.

- Make sure all your clearances stay within the parameters of your grating’s dimensional tolerances.

- If you are installing circular gratings, make your circular obstruction cutouts are at least 2” larger than the obstructions themselves.

Proper Care Floor Gratings

Proper care for floor gratings is essential to maintain their functionality, longevity, and safety. Regular cleaning is crucial to prevent the accumulation of debris, dirt, and other contaminants, ensuring unobstructed drainage and airflow in areas with moisture or heavy foot traffic. Additionally, regular inspections help identify signs of damage, corrosion, or loose parts, which can be promptly addressed to prevent further deterioration or safety hazards. Applying protective coatings or using corrosion-resistant materials in corrosive environments safeguards the floor gratings from deterioration. Properly securing the floor gratings with appropriate hold down clips or clamps is essential to prevent accidental dislodging or movement. Installing locks in public spaces adds an extra layer of security to prevent unauthorized access.

The consequences of improper care for floor gratings can be significant. Neglecting regular cleaning and maintenance can lead to clogged or blocked grates, causing water pooling, unpleasant odors, or compromised indoor air quality. Damaged or improperly secured floor gratings pose safety risks, such as trip hazards or collapse under heavy loads, while lack of maintenance can lead to accidents, injuries, and downtime in industrial settings. Corrosion and lack of maintenance can also result in structural damage, weakening the floor gratings and potentially affecting the supporting infrastructure.

On the other hand, proper care offers several benefits. Regular maintenance significantly extends the life of floor gratings, reducing the need for premature replacements and saving on costs. Well-maintained floor gratings ensure a safe environment for occupants, workers, or visitors, minimizing the risk of accidents. Additionally, clean and properly cared-for floor gratings maintain their intended functionality, providing efficient drainage and ventilation as designed. Ultimately, adhering to a maintenance routine can lead to improved performance, enhanced safety, and potential cost savings by addressing issues early on and preventing major damage.

Standards

Standards for floor gratings in the United States are essential to ensure safety, quality, and compliance with industry requirements. Several acts and governmental or other agencies are involved in creating and enforcing these standards. The Occupational Safety and Health Administration (OSHA) sets workplace safety standards, including regulations for floor gratings used in industrial settings. The American National Standards Institute (ANSI) establishes voluntary consensus standards for various products, including floor gratings, widely recognized and referenced in engineering and construction specifications. The National Association of Architectural Metal Manufacturers (NAAMM) publishes guidelines for the design, manufacture, and use of metal bar gratings. Additionally, the American Society for Testing and Materials (ASTM) develops standards for materials used in floor grating construction.

Floor gratings are classified into different grades based on load-bearing capacity, design, and construction. Common grades include Heavy Duty (HD), Light Duty (LD), and Medium Duty (MD). These grades are determined through rigorous testing and evaluation of structural properties, ensuring the grating can support various loads and resist bending or deformation.

Using floor gratings that do not meet proper standards can lead to serious consequences. These may include compromised safety, increased risk of accidents, and structural failures. Substandard gratings may collapse under normal usage, causing injury or damage, and may not withstand harsh environments, leading to accelerated deterioration or corrosion and requiring frequent replacements, which can be costly and disruptive.

In contrast, utilizing floor gratings that meet proper standards offers significant benefits. It ensures the safety of personnel and visitors, as compliant gratings are designed to handle expected loads and resist potential hazards. Meeting standards also guarantees the gratings’ quality and longevity, reducing the need for frequent replacements and maintenance. Properly graded floor gratings enhance drainage and ventilation systems’ efficiency, making them ideal for various applications, such as industrial plants, commercial buildings, or public spaces. Perhaps most importantly, using compliant floor gratings facilitates smooth project approvals and adherence to building codes, demonstrating a commitment to safety and quality in construction projects.

Things to Consider

If you are interested in purchasing standard or custom floor grates, you need to work with an experienced manufacturer who can provide you with the best product and services possible. We know that there is a lot of competing noise out there on the internet; that’s why we’ve put together a list of industry leading floor grating manufacturers that you can trust. You will find their profiles sandwiched in between all of this industry info. Before you start looking over these profiles, though, we recommend you put together a specifications list for reference. Your list should include things like: application, application environment (indoor, outdoor, rain, snow, corrosion, etc.), standard requirements, budget, timeline, preferred delivery style and preferred installation assistance level. Once you have put this all together, you can start browsing the companies we’ve listed and their available services.

As you browse, frequently consult your list to compare and contrast their services to your needs. Pick out three or four you think have the potential to serve you best, then reach out to each of them for a conversation. Discuss your application at length, and don’t be afraid to ask questions. A good customer service representative will respect your thoroughness and treat you with care. Once you’ve spoken with each company, compare and contrast the information they’ve given you, determining which offers the services and products that most closely align with your needs. Also compare the nature of the conversations, determining which company offers the best customer service. Finally, decide which manufacturer is right for you.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services