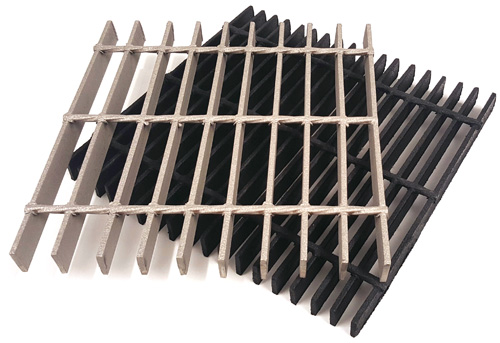

Consider the mind-bending task that gratings accomplish: they are there, and they are not there. They are characterized by their presence as much as they are by their absence, and both qualities are equally important. Some of them have to support the weight of a person, car or piece of machinery while simultaneously allowing air, water or other things to get through. Many gratings, perhaps even a majority of them, are designed as floor gratings. In every commercial, industrial and consumer context, gratings of varying construction and composition are keeping people from slipping and liquids or debris from collecting. Because gratings find themselves in such a diversity of settings, each one must be designed in a way that is appropriate for its application.

Depending on the grate construction material, manufacturing processes differ from each other. Expanded metal grates begin as metal sheets and are slit and expanded by machinery; as the metal expands, the slits become holes. In other cases, metal sheets are perforated using an industrial hole-punch. The former option can be more popular because almost none of the material is wasted during production. In other cases, metal rods, bars or planks are welded or otherwise connected at angles; this method usually produces the sturdiest grating and is frequently used in settings where load-bearing is an important consideration. Still more techniques are involved when making grates out of non-metal materials.

Adding fiberglass to a resin in the plastic production process increases the strength, durability and heat-resistance of the final plastic product. For this reason, fiberglass reinforcement of plastic gratings that will be subject to frequent wear is almost universal. Similarly, metal gratings that are subject to demanding conditions are often galvanized, which means that they are strengthened through a chemical reaction and heat treatment.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services