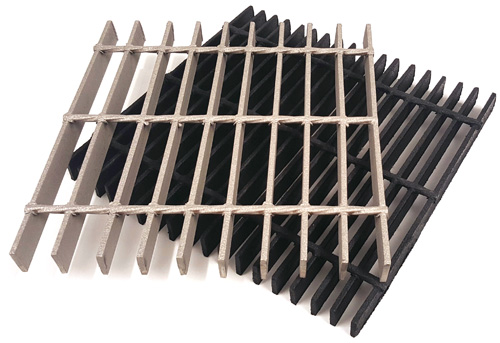

A grating is any regularly-spaced group of nearly identical, parallel, elongated components. Gratings are used for weight-support devices, as filters over drains and vents, and various other applications. Iron, carbon steel, aluminum, and stainless steel are some commonly-used materials used in gratings. Fiberglass grating, which can also be referred to as fiberglass reinforced plastic (FRP grating), is a lightweight and reliable alternative to steel or aluminum gratings. This product is great for use outside or in hostile industrial settings, because it is both corrosion- and fire-resistant. Read More…

All Plastics and Fiberglass prefabricates gratings products including fiberglass gratings, bar gratings and floor gratings. We offer online ordering of our in-stock products to accommodate all our current and potential customers.

Our seasoned engineers are experts at manufacturing durable gratings. These high quality solutions are specialized for a variety of industries. We take pride in saying that all of our manufacturing processes happen right here in the United States. We promise to assist you with all of your needs. You will be satisfied with our long-lasting economical solutions!

We are the experts at creating high quality gratings. Our engineers are eager to handle any of your requests. We care about your order, no matter how big or small. You can count on friendly assistance from the first call. We pay attention to your specific requirements and you are guaranteed to receive your products on-time. These items are easy to install and simple to maintain.

For over 40 years, Ohio has been a leading manufacturer of precision made aluminum grating solutions and offers products in both light duty for pedestrian loading and heavy duty for H20 loading to meet AASHTO standards. Ohio’s products can be manufactured to comply with ADA requirements, are manufactured in the USA and can assist with earning LEED credits. Please call Ohio today!

More Fiberglass Grating Manufacturers

Fiberglass Manufacturing and Properties

Fiberglass is a reinforced plastic material composed of randomly- positioned woven threads and glass fibers that are bonded by a binder agent and combined with a resin. This mixture is heated until molten, then pushed through incredibly small holes to create fiberglass. As a result of this process, incredibly thin glass filaments are produced; these filaments are so thin that their best unit of measurement is the micron (the length of one micron equals the length of one millionth of a meter). There are several uses for these flexible filament threads, including as fiberglass gratings. Fiberglass has an exceptional strength-to-weight ratio and is up to 70% lighter than steel. Even though they are lighter than steel gratings, FRP gratings can still support vehicular applications with sufficient strength. Fiberglass is a good electrical insulator; steel cannot match the electrical resistivity of fiberglass even at much lower thicknesses of fiberglass. Since fiberglass is made of minerals, it is also inflammable by nature.

Types of FRP Grating

FRP Pultruded Grating

Pultruded (pulled) forms can be used to build FRP gratings. Fiberglass rovings and mats are dragged through guides, placed in a resin bath, wrapped in a surface veil, and then pulled through a heated die to create the appropriate bar shape (I-Bars, T-Bars, etc.). The bars are pulled, then they are drilled for cross-rods, and finally, they are put together by attaching the cross-rods. Finally, epoxy is used to bond these cross-rods, which lock the bars into place and guarantee their stability. Although any available resin can be used, pultruded gratings are commonly made using either an isophthalic polyester resin or a vinyl ester resin.

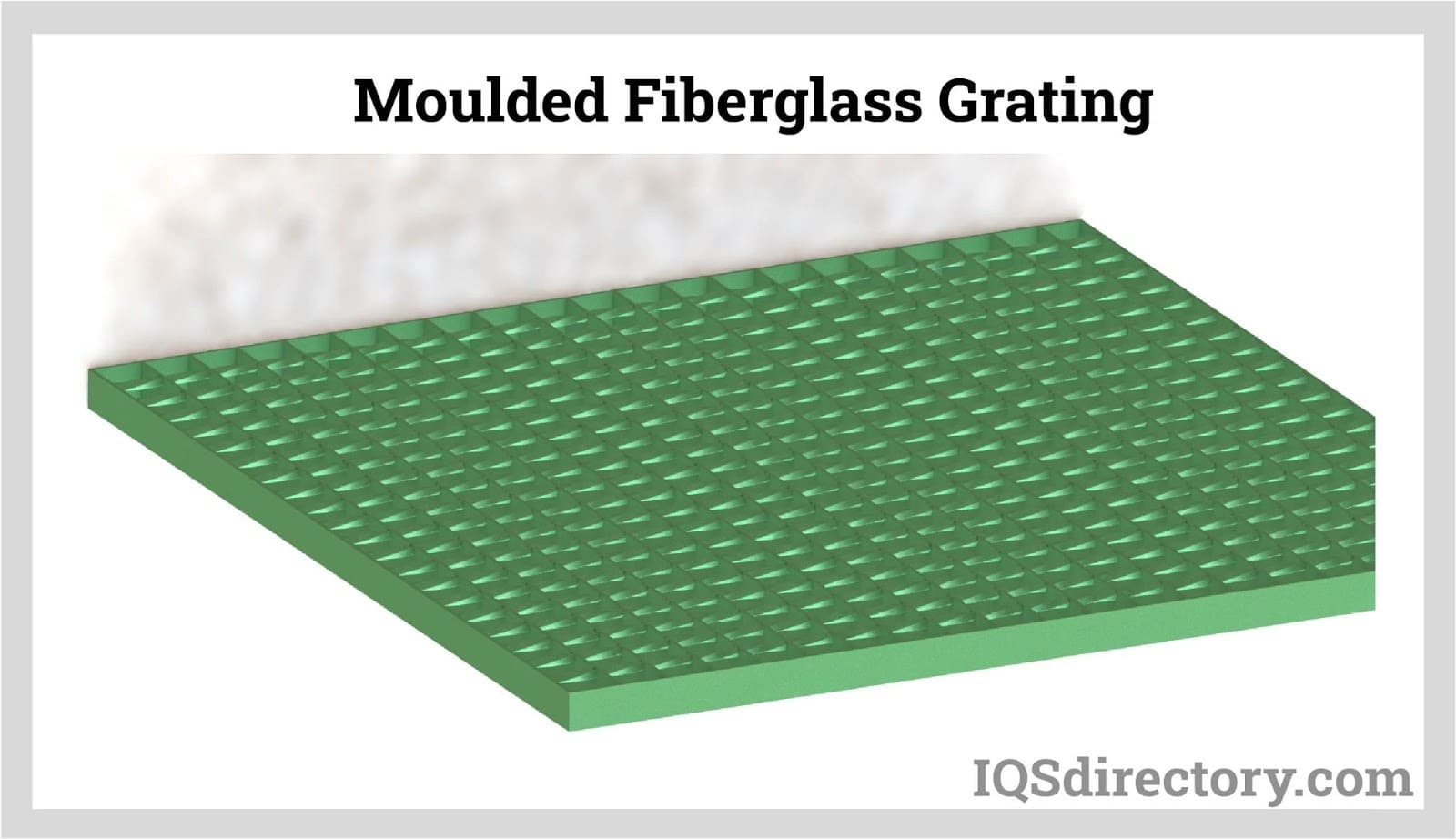

FRP Moulded Grating

This particular fiberglass-reinforced plastic grating is moulded into required shapes. It is a composite material made of laminated fiberglass covered in polyester or vinyl ester resin (to a degree of 65%). This type of Fiberglass Reinforced Plastic grating provides the best strength due to its precise manufacturing process. This FRP grating also has outstanding corrosion resistance across a broad pH range of both acidic and caustic chemicals thanks to its special characteristics. Even in the most severe and corrosive environments, moulded Fiberglass Reinforced Plastic (FRP) grating performs superbly and reliably.

Mini Mesh Fiberglass Grating

The 12 mm (less than a half inch) openings of mini mesh fiberglass grating prevent things from falling through, which makes it perfect for overhead platforms and walkways in commercial and industrial settings. It is long-lasting, low-maintenance, simple to install, and it is highly resistant to slips, fire, and rust. Its small mesh also provides a fiberglass grating which can be used as a pathway without worrying about people's work shoes becoming tangled up in its small apertures.

Applications of Fiberglass Grating

- Fiberglass grating is utilized in many industrial locations (ladders, stairs, ladders, walkways, etc.) due to its anti-slip and anti-corrosion properties.

- Cooling towers must be shielded from rust, corrosion, and other safety hazards since they are constantly damp. Fiberglass is employed in these towers as screening material because of its great corrosion-fighting qualities.

- Fiberglass grating is employed as a barrier to prevent people and animals from entering dangerous areas.

- Fiberglass grating is used in fountains and aquariums of all sizes to support rocks and aid in the circulation and filtration of water from beneath the rocks.

- Fiberglass grating is used in large public fountains to shield spray headers and lighting from harm. Additionally, it prevents individuals from perishing in the fountains.

- Fiberglass grating is used for electronic refining components subject to chemical corrosion where other grating materials would not be suitable under similar situations.

- Fiberglass's resistance to chemical corrosion is useful in pulp and bleach mills due to high levels of chemicals required to produce these products.

Choosing the Proper Fiberglass Grating Manufacturer

To ensure you have the most productive outcome when purchasing fiberglass gratings from a fiberglass grating manufacturer, it is important to compare several companies using our directory of fiberglass grating manufacturers. Each fiberglass grating manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each fiberglass grating business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple companies with the same form.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services