Plastic grating is able to meet the requirements for grating in chemical, refinery, pulp and paper, offshore and marine, water and waste water, electronics, food processing applications and more. Read More…

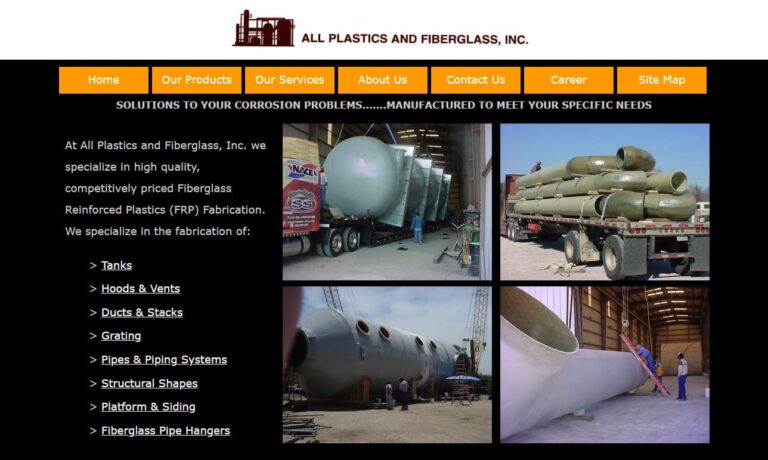

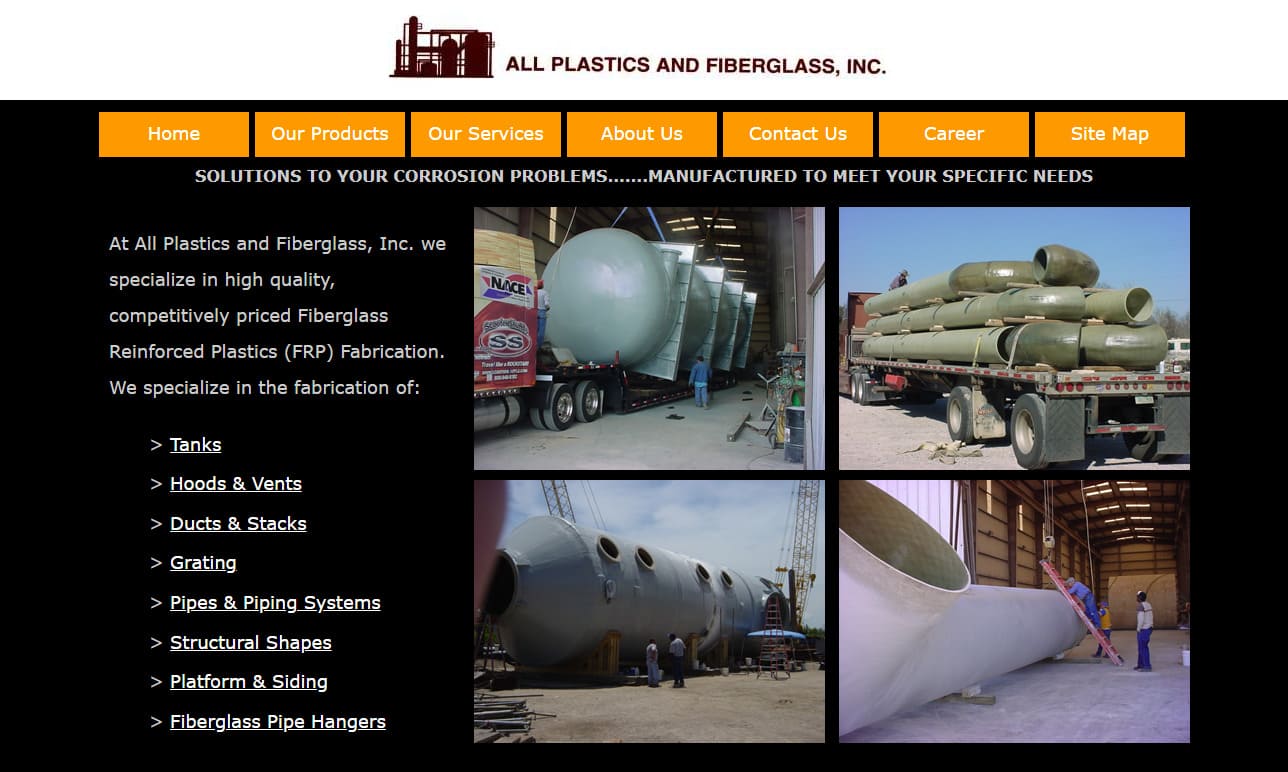

All Plastics and Fiberglass prefabricates gratings products including fiberglass gratings, bar gratings and floor gratings. We offer online ordering of our in-stock products to accommodate all our current and potential customers.

Strongwell is the world's leading pultruder of FRP structural components. Strongwell’s products include structural shapes, plate, fiberglass grating, building panels, handrail systems, ladder & cage systems, bridge decks, cooling tower components, planking systems, and custom shapes. If you would like more information about our company then please let us know!

Indiana is the benchmark other manufacturers strive to achieve. This financially strong, family owned company with over 35,000 sq. ft. of manufacturing area offers cost-effective, quality structural, decorative products, including precision crafted light & heavy duty welded gratings. Operating in accordance with NAAMM standards, Indiana has built its reputation on "personal service".

At Ryan Herco Flow Solutions, we take pride in delivering durable and reliable floor gratings designed to meet the highest standards of performance and safety. We understand the critical role that flooring systems play in industrial and commercial environments, and we engineer our floor gratings to provide strength, stability, and long-lasting value.

More Plastic Grating Manufacturers

Plastic Grating: Lightweight, Durable, and Corrosion Resistant Flooring Solutions

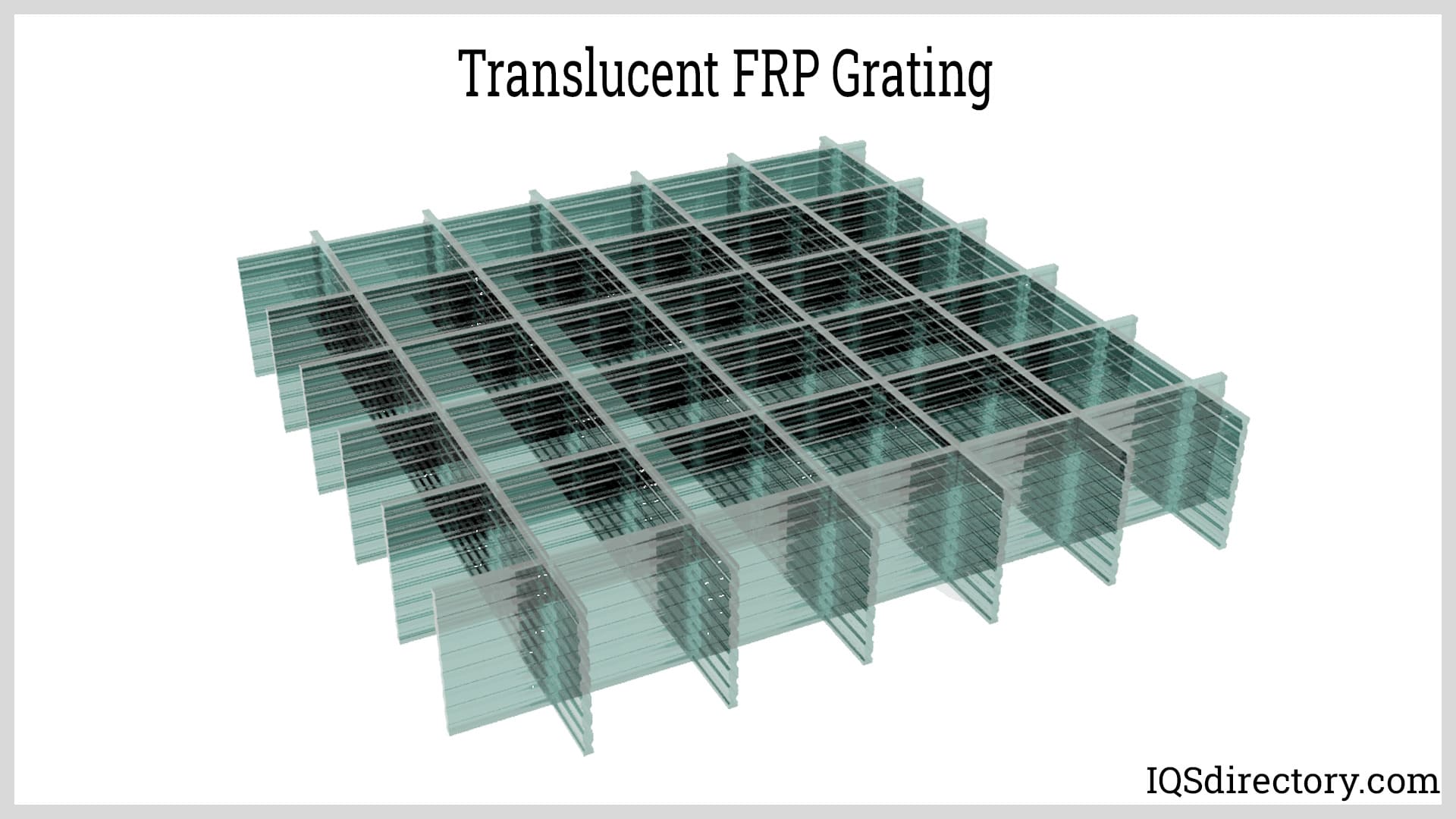

Plastic grating, also known as fiberglass reinforced plastic (FRP) grating, is an increasingly popular flooring and structural solution for a wide array of commercial, industrial, and marine applications. As a lightweight yet strong alternative to traditional aluminum grating, steel, and other metal grating products, plastic grating delivers superior corrosion resistance, ease of installation, and long-term value for facility owners and maintenance teams.

What is Plastic Grating?

Plastic grating, often manufactured from resin-based fiberglass composites, is engineered to provide a robust walking surface, load-bearing platform, or protective covering. This type of industrial grating is available in several configurations, including molded and pultruded grating, and can be fabricated to meet custom dimensions, load requirements, and functional needs. Its non-conductive nature, slip resistance, and resilience to harsh environments make it an ideal solution across industries.

Key Applications and Use Cases for Plastic Grating

Plastic grating’s versatility has led to its adoption in a wide range of commercial and industrial environments. Typical use cases include:

- Industrial floor systems for manufacturing plants, chemical processing facilities, and food & beverage operations

- Walkways and catwalks in water treatment plants, factories, power generation sites, and coastal areas

- Work platforms designed for heavy traffic and load-bearing requirements

- Industrial and commercial stairs and stair treads requiring enhanced safety and durability

- Ramps, trench covers, and drain grates where liquid drainage and slip resistance are critical

- Marine and seaside applications such as docks, piers, and ship decks exposed to saltwater environments

- Architectural and public spaces for decorative yet functional flooring, screening, or sunshades

Looking for the right plastic grating for your project? Contact us for recommendations tailored to your application and load requirements.

Strength and Corrosion Resistance: Comparing Plastic Grating to Metal Grating

One of the primary reasons facility managers and engineers choose plastic grating over traditional metal options is its superior resistance to corrosion. The resin matrix within fiberglass reinforced plastic (FRP) grating provides exceptional protection against chemicals, saltwater, and environmental exposure that typically degrade steel, iron, or steel grates over time. This makes plastic grating a low-maintenance, cost-effective, and long-lasting solution for environments where corrosion is a major concern.

Plastic grating not only resists rust, oxidation, and chemical attack, but also delivers high impact resistance and strength-to-weight ratios that outperform many metal alternatives. The glass fibers in FRP grating reinforce the structure, allowing it to withstand heavy loads, repeated use, and mechanical stress. This makes plastic and fiberglass grating suitable for areas with heavy foot traffic, machinery, and equipment movement.

Decision Factors: Why Choose Plastic Grating?

- Corrosion resistance: Ideal for chemical plants, wastewater facilities, marine environments, and anywhere exposure to corrosive substances is likely.

- Lightweight design: Easier to transport, handle, and install versus steel or aluminum grating; often requires less structural support.

- Superior impact strength: Withstands heavy loads and repeated impacts without cracking or deforming.

- Non-slip surface: Textured bars or grid surfaces greatly reduce slip and fall accidents, supporting workplace safety initiatives.

- Non-conductive properties: Provides electrical and thermal insulation—critical for electrical substations, switchgear rooms, and power plants.

- Low maintenance: No need for painting, galvanizing, or surface coatings; easy to clean and resistant to mold, mildew, and UV exposure.

- Custom fabrication: Can be manufactured to fit unique shapes, sizes, and design specifications, including cut-outs for piping or equipment.

Comparing Plastic Grating to Other Grating Materials

How does plastic grating stack up against metal grating options such as steel, iron, and aluminum grating? Here’s a side-by-side comparison to help you evaluate the best flooring solution for your facility or project:

| Feature | Plastic/Fiberglass Grating | Steel Grating | Aluminum Grating |

|---|---|---|---|

| Weight | Very light; easy to handle | Heavy; requires lifting equipment | Lighter than steel, heavier than plastic |

| Corrosion Resistance | Excellent | Poor to Moderate (requires coatings) | Good (may corrode in saltwater) |

| Maintenance | Low; no coating required | High; needs regular painting/galvanizing | Low to moderate |

| Slip Resistance | High (textured surface) | Moderate (depends on finish) | Moderate |

| Custom Fabrication | Easy to cut and shape | Requires specialized tools | Can be fabricated, but less flexible than plastic |

| Cost | Moderate (lower life cycle cost) | Low upfront, high maintenance | Higher upfront, moderate maintenance |

Considering a switch from steel or aluminum grating to plastic grating?

Explore our steel grating and aluminum grating pages for detailed comparison, or contact our experts for a personalized assessment based on your facility’s needs.

Benefits of Plastic Grating for Safety and Compliance

One of the chief benefits of plastic and FRP grating is its role in improving workplace safety. The anti-slip surface reduces the risk of slips, trips, and falls—one of the leading causes of workplace injuries in industrial and commercial settings. Open grid designs allow for efficient drainage of water, mud, snow, and debris, helping to keep walking and working surfaces dry and secure, even in outdoor or washdown environments.

Plastic grating is also compliant with many OSHA and NFPA safety standards, making it a preferred choice for organizations focused on regulatory compliance and risk reduction. Its non-conductive properties are particularly important in electrical and high-voltage environments, reducing the risk of electrical shock.

Installation and Maintenance Advantages

Plastic grating is engineered for ease of installation and reduced maintenance burden. Compared to steel or metal grating systems, plastic grating:

- Requires minimal on-site cutting or modification—many panels are available in standard sizes or can be fabricated to exact project specs.

- Is lightweight, so it can be handled and installed by smaller crews without heavy lifting equipment.

- Allows for rapid installation, reducing labor costs and minimizing facility downtime.

- Does not require post-installation finishing, such as painting, galvanizing, or anti-corrosion coatings.

- Is easy to clean with standard detergents and water; resists staining, mold, and mildew.

- Offers a long service life, even in harsh weather or aggressive chemical environments.

How do you install plastic or fiberglass grating?

Plastic grating panels are typically secured to structural supports using stainless steel or FRP fasteners. For elevated or raised applications, grating clamps or hold-down clips ensure panels stay firmly in place. Many manufacturers provide installation guides, and custom fabrication can include pre-drilled holes or cut-outs for seamless integration with existing infrastructure.

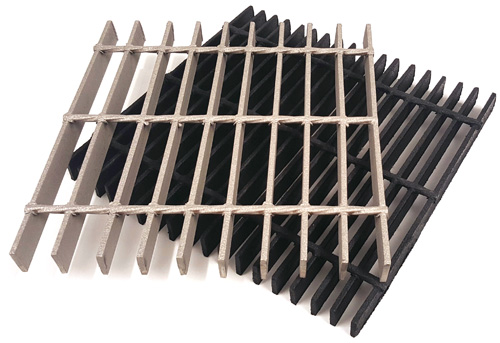

Types of Plastic Grating: Molded vs. Pultruded

When selecting plastic grating, buyers often choose between molded and pultruded fiberglass grating:

- Molded Fiberglass Grating: Manufactured by arranging glass fibers in a mold, then saturating with resin. Molded grating offers excellent bi-directional strength and is ideal for applications with cut-outs or penetrations.

- Pultruded Fiberglass Grating: Produced by pulling continuous glass fibers through a resin bath and heated die. Pultruded grating provides superior span capability and is best for applications requiring higher load capacities and longer spans.

Both types of FRP grating offer outstanding corrosion resistance, slip resistance, and design flexibility. Your choice depends on specific project requirements, including load ratings, span, and required customizations.

Customization, Finishing, and Aesthetic Options

Plastic grating can be tailored to meet unique design and functional requirements. Options include:

- Custom panel sizes, shapes, and thicknesses

- Color choices to match facility branding or increase visibility in safety zones

- Surface finishes such as grit, smooth, or patterned for enhanced traction or easier cleaning

- Add-on features like kick plates, stair nosings, or anti-slip nosings

- Cut-outs for pipe penetrations, cable trays, or mounting brackets

Need advice on selecting the right grating configuration? Talk to a grating specialist for expert guidance on customization and product selection.

Industry-Specific Applications for Plastic Grating

Plastic and fiberglass grating are trusted in a range of industries where safety, durability, and corrosion resistance are required. Popular sectors include:

- Water and wastewater treatment: Walkways, access platforms, and trench covers

- Marine and offshore: Ship decks, docks, and piers exposed to saltwater corrosion

- Chemical processing: Flooring and work platforms exposed to aggressive chemicals

- Food and beverage: Hygienic, slip-resistant floors for processing and packaging areas

- Transportation: Station platforms, ramps, and drainage covers

- Mining and energy: Non-conductive walkways in hazardous or explosive environments

- Commercial architecture: Decorative screens, sunscreens, and infill panels

What are the most important factors when choosing plastic grating?

Buyers should consider:

- Load-bearing requirements and span distances

- Exposure to chemicals, UV, and weather

- Slip resistance needs

- Installation environment (indoor vs. outdoor, marine vs. industrial)

- Compliance with OSHA, ADA, and other safety codes

- Cost of ownership over the product lifespan

- Customization and color options

Frequently Asked Questions About Plastic Grating

Is plastic grating as strong as metal grating?

While plastic grating is lighter than steel or aluminum, advanced fiberglass reinforced plastic (FRP) grating can achieve comparable or superior strength-to-weight ratios. Pultruded FRP grating, in particular, is engineered for demanding applications and can support significant loads when properly specified and installed.

How long does plastic grating last?

Plastic grating, especially FRP grating, offers a service life of 20+ years in many demanding environments. Its resistance to rust, corrosion, UV rays, and impact ensures longevity with minimal maintenance requirements, making it a cost-effective flooring solution over the long term.

How do I clean and maintain plastic grating?

Most plastic grating products can be cleaned with water, mild detergents, or pressure washers. They are designed to resist mold, mildew, staining, and chemical buildup, so regular cleaning is simple and cost-effective. No painting or coating is required.

Can plastic grating be recycled?

Many types of FRP and plastic grating can be recycled or repurposed at the end of their service life. Always consult your manufacturer for specific recycling recommendations and local disposal guidelines.

What are the lead times and shipping considerations for plastic grating?

Lead times depend on product type, quantity, and level of customization. Many standard sizes are in stock with fast shipping, while custom-fabricated panels may require several weeks. Lightweight construction helps reduce shipping costs versus metal grating.

Get a Quote or Request Samples

Ready to upgrade your facility with high-performance, corrosion-resistant plastic grating? Request a quote today or ask for free samples to evaluate in your application. Our team of experts is available to help you compare products, select the right specifications, and ensure compliance with safety and building code requirements.

Additional Resources

Whether you need lightweight, corrosion-proof grating for a new build or an upgrade to existing infrastructure, plastic and fiberglass grating provide a smart, low-maintenance, and highly customizable solution. Discover the difference for your facility and enjoy the long-term benefits of safety, durability, and value.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services