Bar Grating

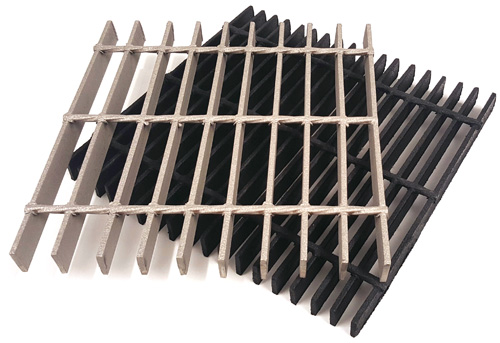

Any regularly spaced group of nearly identical, parallel, elongated components is called grating. Bar grating is made to support large loads with little weight. Bar gratings are made of bearing bars and cross bars. The bearing bar is the main load-bearing bar that runs in the same direction as the span. The cross bars are connectors that cross or pass through the bearing bars and are formed of strip or roll bars. Cross bars can be mechanically locked, forged, or welded. Grating is often made from steel, aluminum, and fiberglass, to name a few. Read More…

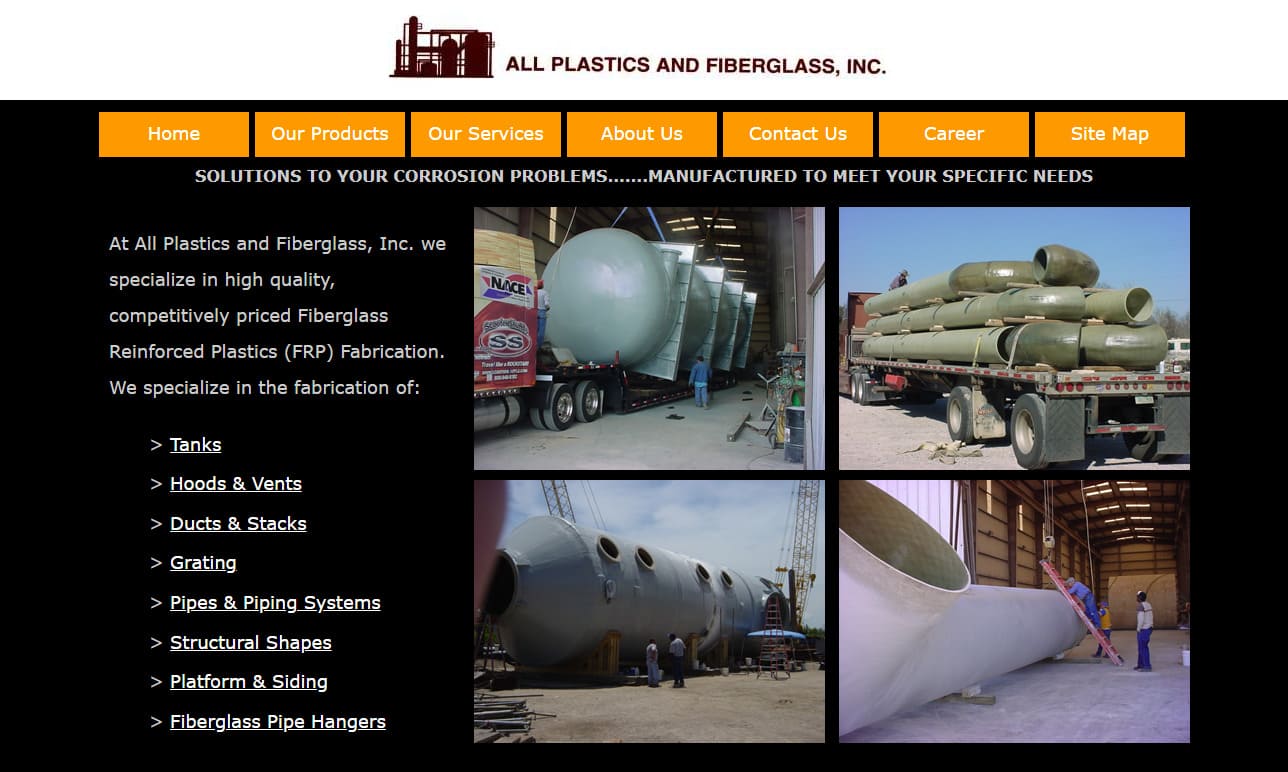

All Plastics and Fiberglass prefabricates gratings products including fiberglass gratings, bar gratings and floor gratings. We offer online ordering of our in-stock products to accommodate all our current and potential customers.

Our seasoned engineers are experts at manufacturing durable gratings. These high quality solutions are specialized for a variety of industries. We take pride in saying that all of our manufacturing processes happen right here in the United States. We promise to assist you with all of your needs. You will be satisfied with our long-lasting economical solutions!

We are the experts at creating high quality gratings. Our engineers are eager to handle any of your requests. We care about your order, no matter how big or small. You can count on friendly assistance from the first call. We pay attention to your specific requirements and you are guaranteed to receive your products on-time. These items are easy to install and simple to maintain.

For over 40 years, Ohio has been a leading manufacturer of precision made aluminum grating solutions and offers products in both light duty for pedestrian loading and heavy duty for H20 loading to meet AASHTO standards. Ohio’s products can be manufactured to comply with ADA requirements, are manufactured in the USA and can assist with earning LEED credits. Please call Ohio today!

More Bar Grating Manufacturers

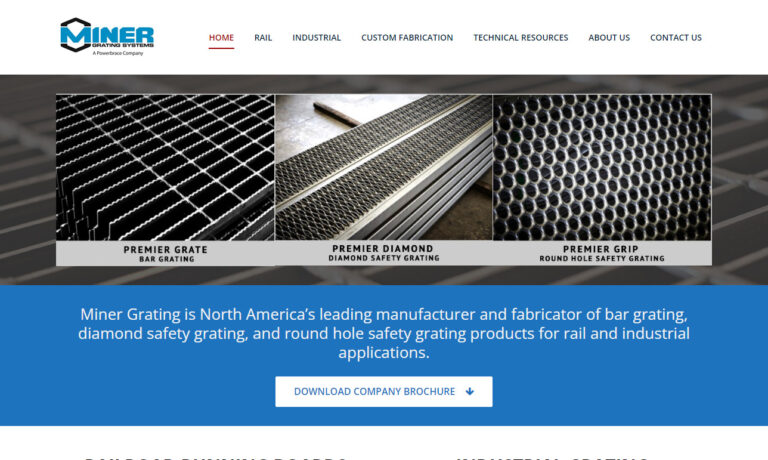

Types of Bar Grating

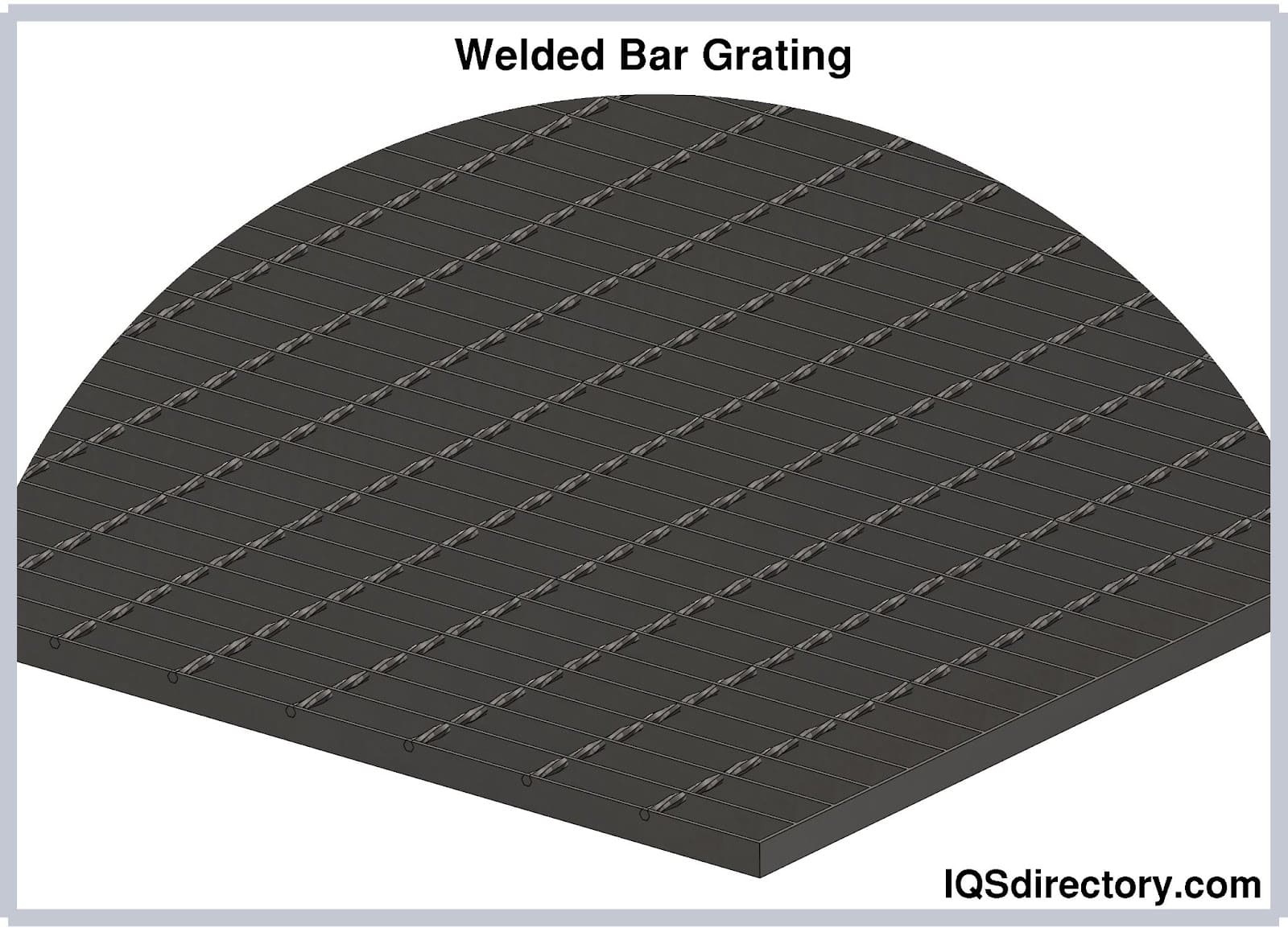

Welded

For most industrial applications, welded bar grating is a practical and affordable solution. Drawn cross bars and rectangular bearing bars are forged together to create a fused, long-lasting connection to weather harsh conditions. Welded steel grating is non-slip, corrosion-resistant, has good drainage, and can support heavy weight.

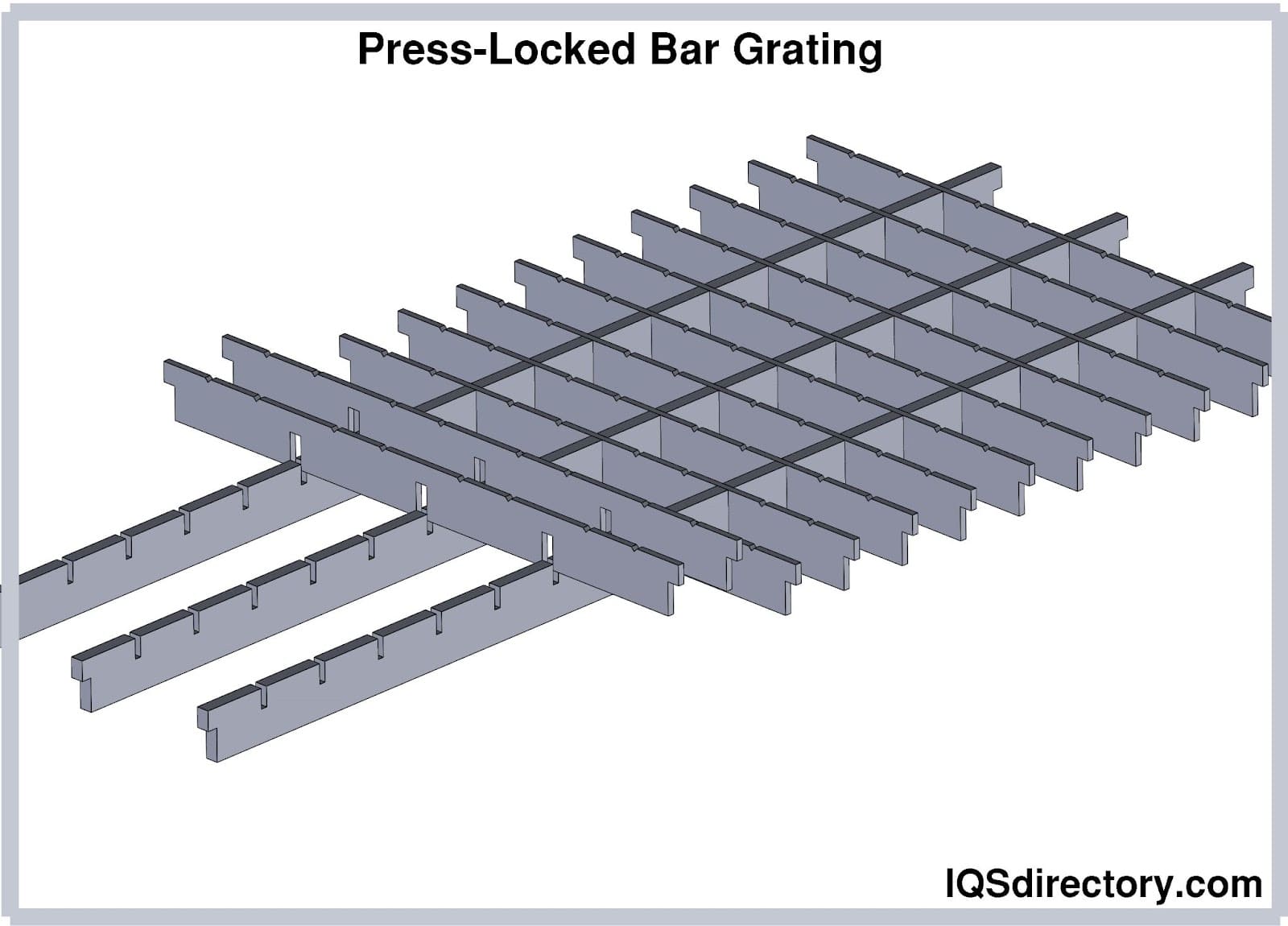

Press-locked

Press-locked grating is created by using immense hydraulic pressure to lock crossbars into notched bearing bars permanently. This glues the close-tolerance slotted bars together. Notching and pressing the cross and bearing bars together creates a smooth, uniform surface. This method creates an attractive appearance that blends well with architectural plans. Press-locked metal bar grating is available in many sizes, materials, and bar apertures.

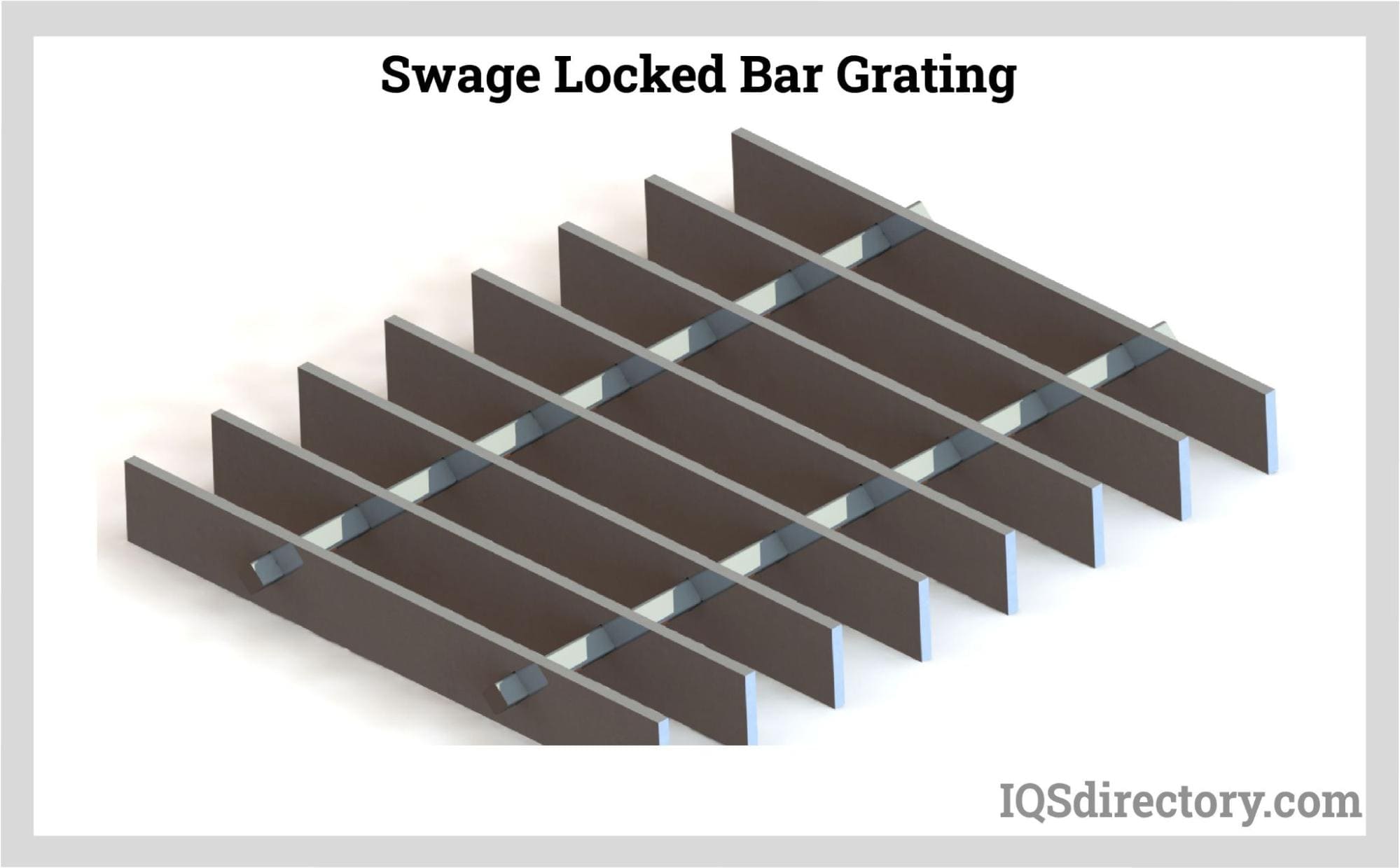

Swage Locked Bar Grating

Swage locked bar grating features tube cross bars inserted into bearing bars with pre-punched holes. Afterward, a swaging reshaping procedure will permanently secure the crossbars. Swage-locked bar grating has clear lines and a distinctive appearance because the cross bars are recessed below the top surface of the bearing bars. In addition, contemporary swaging technology can add attached intersections.

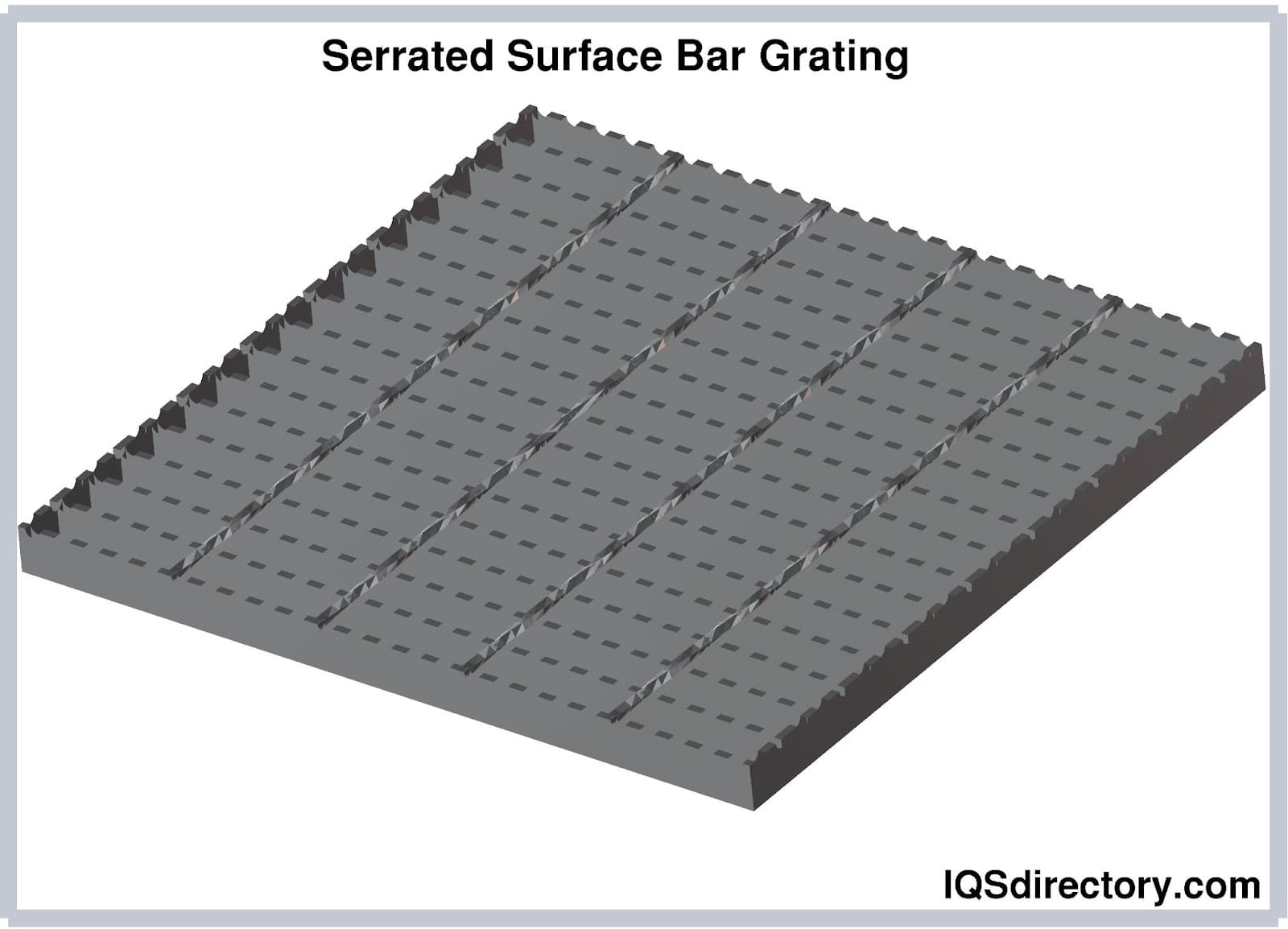

Serrated Surface

Serrated surface bar gratings have a jagged edge, like a saw. Serrated surfaces may be the best choice if the grating is used in wet or slippery environments. The serrated grating requires a thicker bearing bar depth to maintain a strength comparable to non-serrated gratings.

Riveted Bar Grating

Riveted gratings can be made of stainless steel, aluminum, and carbon steel. The bearing bars are evenly spaced with a riveted area in the middle. The riveted grating is the best option if the grating has to support heavier weights. Reticulated bars are riveted to bearing bars, creating the strength to endure rolling traffic from vehicles. Riveted bar gratings offer a higher load-carrying capacity than a welded bar or swage-locked grating.

Applications and Benefits of Bar Grating

- Bar grating fencing is attractive, strong and rigid enough to offer a high level of security. Bar grating is ideal for security purposes.

- Gratings often compose the floors and walkways of commercial and industrial buildings where there may be liquid or waste. A floor grating's higher tread enhances safety by avoiding water accumulation or slippery surfaces.

- Bar gratings often create ramps and carry vehicles and other large objects onto elevated platforms. On mobile and fixed loading ramps, bearing bars are oriented in the direction of the traffic flow. The serrated grating provides traction.

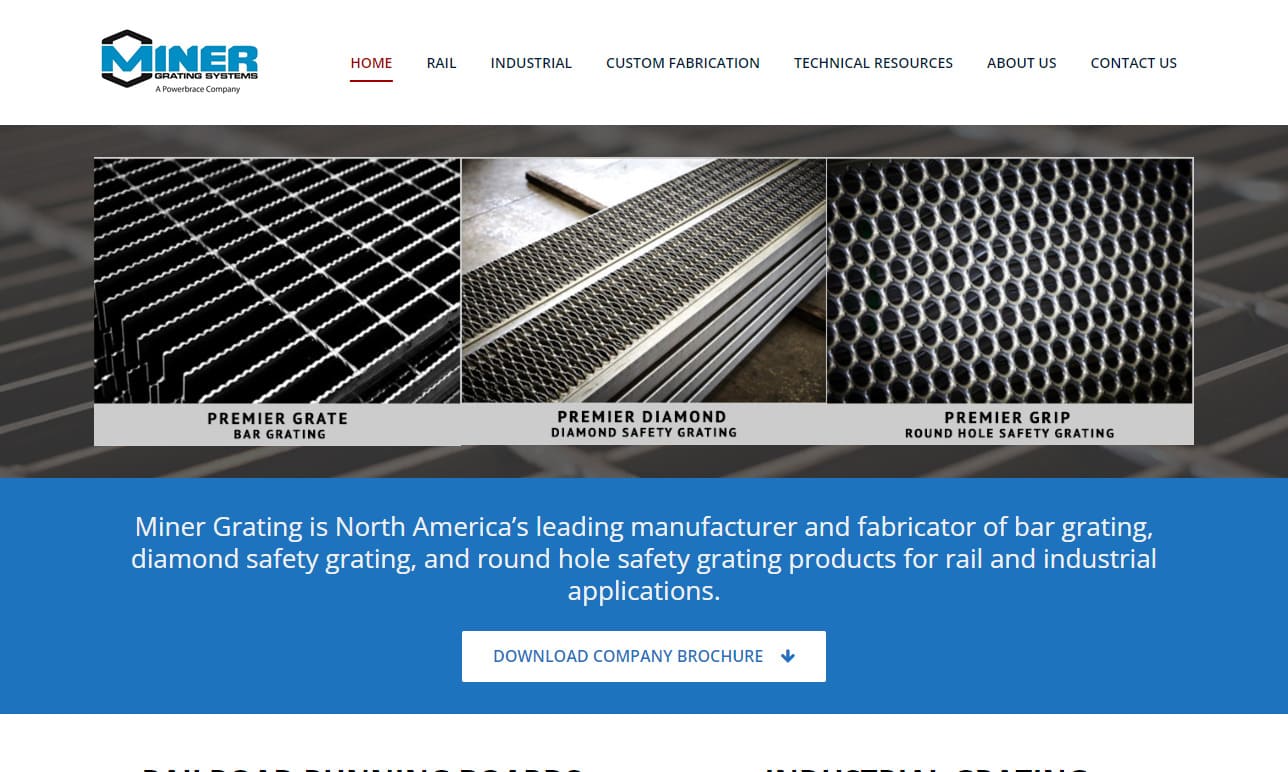

- Bar grating creates the running boards, brake stairs, platforms, and walkways installed in freight cars, locomotives, and railcars. The grating lowers the risk of falling with cleverly designed mesh serrated bar grating.

- Ventilation grates generate airflow using a unique aeration system. They integrate affordability, stability, and functionality into a single component. Ventilation gratings are particularly useful in the agricultural sector. They are ideal for the ventilated storage of dry bulk products.

- Bar grating can provide a distinctive, modern style for architectural highlights and be used as security barriers for equipment protection and highway guardrails. Aluminum bar grating has a strong strength-to-weight ratio, is lightweight, and is long-lasting. Aluminum bar grating is easy to install and transport, not to mention corrosion-resistant and easy to maintain.

Choosing the Right Bar Grating Manufacturer

To ensure you have the most beneficial outcome when purchasing bar gratings from a bar grating manufacturer, it is important to compare several companies using our directory of bar grating manufacturers. Each bar grating manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each bar grating business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to communicate with multiple bar grating businesses with the same form.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services