Typically constructed from aluminum, steel or stainless steel, metal grates are popular for outdoor ramps and stairs, can be used to cover storm drains and sewers and in factory floors where it is necessary to keep the floor free of debris and liquids, or where a non-slip surface is required. Read More…

All Plastics and Fiberglass prefabricates gratings products including fiberglass gratings, bar gratings and floor gratings. We offer online ordering of our in-stock products to accommodate all our current and potential customers.

Our seasoned engineers are experts at manufacturing durable gratings. These high quality solutions are specialized for a variety of industries. We take pride in saying that all of our manufacturing processes happen right here in the United States. We promise to assist you with all of your needs. You will be satisfied with our long-lasting economical solutions!

We are the experts at creating high quality gratings. Our engineers are eager to handle any of your requests. We care about your order, no matter how big or small. You can count on friendly assistance from the first call. We pay attention to your specific requirements and you are guaranteed to receive your products on-time. These items are easy to install and simple to maintain.

For over 40 years, Ohio has been a leading manufacturer of precision made aluminum grating solutions and offers products in both light duty for pedestrian loading and heavy duty for H20 loading to meet AASHTO standards. Ohio’s products can be manufactured to comply with ADA requirements, are manufactured in the USA and can assist with earning LEED credits. Please call Ohio today!

More Metal Grate Manufacturers

Metal grates offer a grate or grid which provides the strength of a solid piece of metal with the advantage of allowing light, liquid, air and small debris to pass through it, preventing unwanted and potentially dangerous accumulation on the surface of a walkway or floor etc.

Metal grates can also serve as a protective wall around machinery or heaters in order to increase equipment use safety. While fiberglass and plastic are also often used in the construction of grating, metals offer extreme strength and load bearing qualities that are necessary in applications for many industries.

Metallic materials offer malleability, ductility, strength and thermal and electrical conductivity which may be required by applications in industries including food and chemical processing, architecture, waste water treatment, paper milling and marine or oil rigs.

Stainless steel grates offer the added benefit of corrosion resistance and are a popular choice for applications which include exposure to corrosive substances.

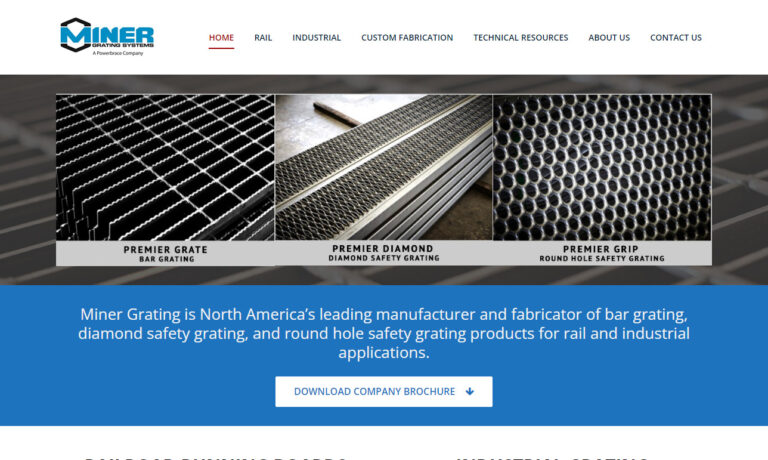

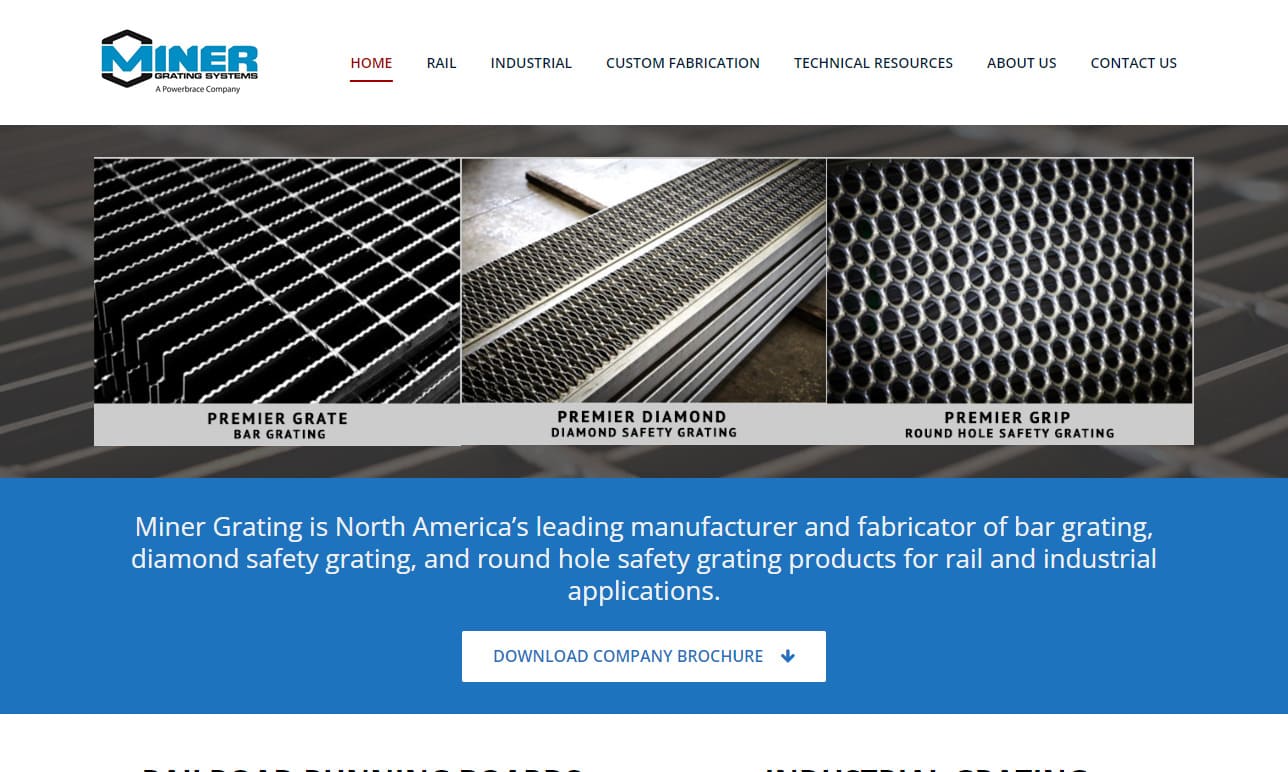

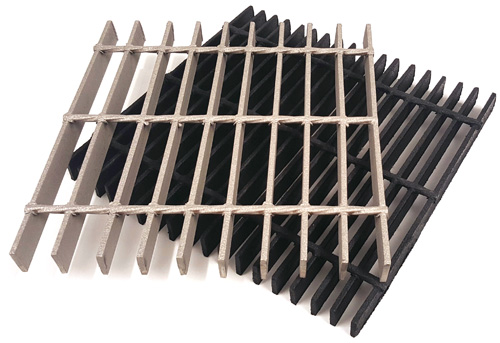

The two main types of fabrication used for metal grates are expanded metal and bar grating. Expanded metal grating is produced from a solid metal plate that has been perforated and stretched, generally into a diamond shape, although this can change according to the requirements of an application.

Expanded metal has a greater strength-to-weight ratio than solid metal and allows liquid, air, and light through while still remaining solid enough to serve as a floor or barricade. The expanding process results in a structurally strong product that will not unravel or come apart at the joints.

Furthermore, expansion as a metal fabricating process results in minimal material waste as almost all of the metal plate is used. Bar grating, in comparison, is a type of grating made with thick metal or fiberglass bars that have been welded, swaged, pressure-locked, or riveted together.

They are commonly used for strong support purposes. The most common spacing configuration of bar grating is rectangular, although it may be reinforced with diagonal bars, forming triangle-shaped spaces that face one another in a diamond configuration.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services